count: [2016-01-19] [Close]

Good news from French Atomic Energy Commission (CEA) / Magnetic Confinement Fusion Research Institute (IRFM): Two kinds of test mockups of tungsten/copper (W/Cu) plasma facing component (PFC), developed at Institute of Plasma Physics Chinese Academy of Sciences (ASIPP) for CEA’s Tungsten Environment in Steady-state Tokamak (WEST) project showed outstanding performance in the high heat flux (HHF) tests carried out by CEA independently.

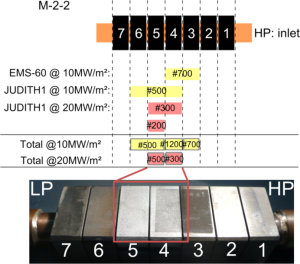

According to IRFM test reports, one W block of the W/Cu monoblock mockup has exceeded the International Thermonuclear Experimental Reactor (ITER) requirements of 300 cycles set for 20 MW/m2 HHF. One W block of the W/Cu monoblock mockup withstood 1200 cycles at heat load of 10MW/m2 and 300 cycles at 20MW/m2, and the other block withstood 500 cycles of 10MW/m2 and 500 cycles of 20MW/m2 (Fig.1).

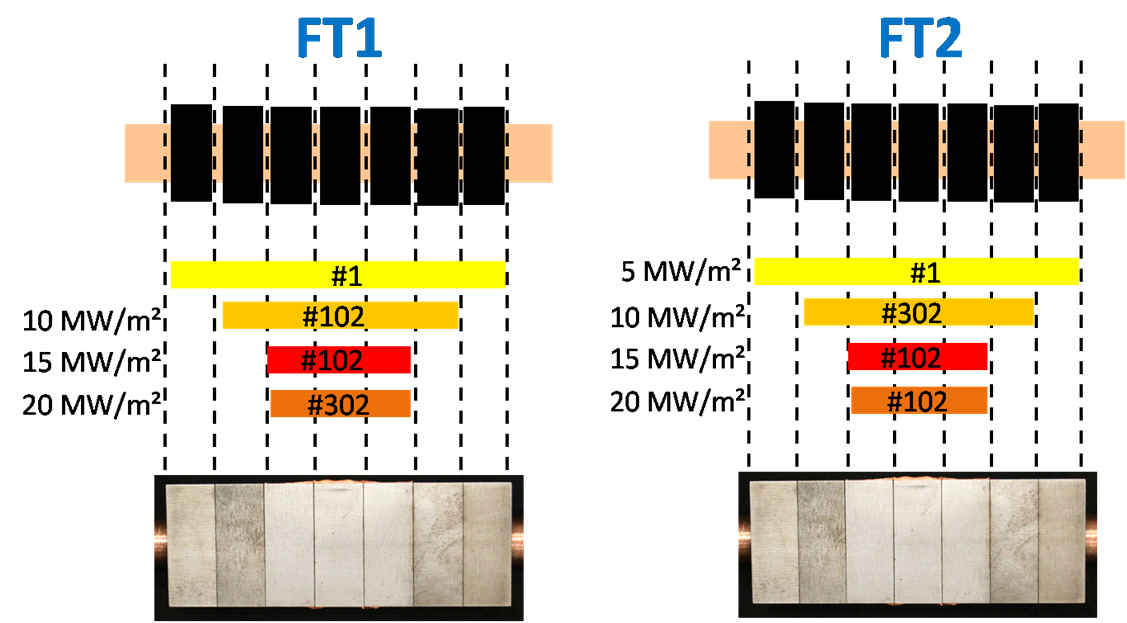

As for the W/Cu flat-type PFC, the mockup FT1 (left in Fig. 2) withstood 102 cycles of 10MW/m2, 102 cycles of 15MW/m2 and 302 cycles of 20MW/m2 in succession; the mockup FT2 (right in Fig. 2) withstood 302 cycles of 10MW/m2, 102 cycles of 15MW/m2 and 102 cycles of 20MW/m2. The results of the flat-type mockups are far beyond the ITER design requirement of 5MW/m2, which, to our knowledge, have set new records.

The two types of W/Cu PFCs will be used for the ITER divertor due to their advantages of high heat resistance, low sputtering rate, low tritium retention and high thermal conductivity, etc. However, it is very difficult to weld tungsten and copper together because of great difference in their thermo-mechanical properties.

ASIPP’s Experimental Advanced Superconducting Tokamak (EAST) is the first tokamak device equipped with ITER-like W divertor in the world, which benefits from the technology breakthrough of large scale industrial production of actively cooled W/Cu-PFCs developed by ASIPP team and its collaborators in China. It will, together with the following divertor physics experimental campaigns, provide precious experience for solving the engineering and physics issues facing the ITER divertor project.

Since 2010, Fusion Reactor Materials Science & Technology Division of ASIPP has cooperated with Advanced Technology & Materials Co., Ltd and Xi’an Jiaotong University to develop manufacturing and inspection technology of W/Cu PFCs for ASIPP’s EAST Mega-Science project. After three years’ research and development and nearly one year’s batch production, the EAST upper divertor was upgraded into the W/Cu-PFCs in early 2014. After the 2014 EAST campaign, the damaged W/Cu PFCs were repaired and the manufacturing process has been optimized significantly. During the 2015 EAST campaign, the W/Cu upper divertor withstood successfully the whole baking phase and tens of shots long pulse plasma discharges. (Qiang LI and Fang DING report)

Fig.1. Test results of W/Cu monoblock mockups

Fig.2. Test results of W/Cu flat-type mockups