count: [2011-09-07] [Close]

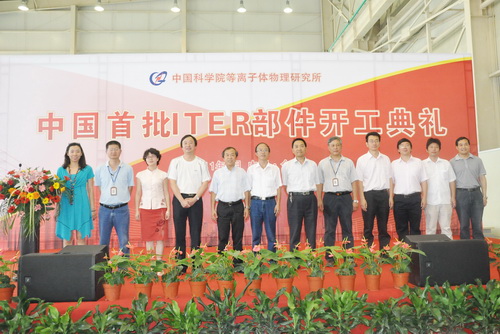

The Commencement Ceremony for China First Batch of ITER Components was held in ASIPP in mid-August, marking China’s ITER conductor task is formally coming to the mass production phase. Luo Delong, chief of China International Nuclear Fusion Energy Program Executive Centre, Wang Yingjian, director of Hefei Institute of Physical Science, and ASIPP director Li Jiangang and other leaders attended this ceremony.

Luo Delong sent his congratulations to ASIPP and gave a brief introduction of ITER project. He said taking part in ITER project would improve Chinese overall level in the field of nuclear fusion.

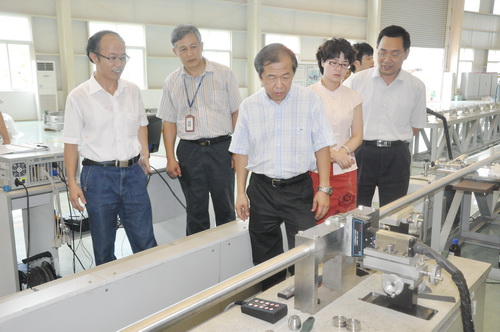

The ceremony was held in a 4000m2 manufacture workshop, which is specifically built for superconducting conductors’ development and manufacture; besides, the first 1000m-long jacketing line in the world has been built here. All these have laid a good foundation for complement of procurement arrangement task. On behalf of the undertaking groups, Wang Yingjian and Li Jiangang expressed the construction groups have faith and commitment to meet international requirements and to provide qualified components.

Backgroud information

Superconducting conductor is one of the key technologies in ITER device, of which quality is very important. In the past 3 years, with the support of National Ministry of Science and Technology and China Fusion Center, our researchers have established a close cooperation with domestic and foreign research institutions and industrial manufacturers, such as Western Superconducting Technologies Co.,Ltd, Nantong Shenhai Special Plating Co., Ltd, Zhengjiang Jiuli Hi-tech Metals Co.ltd, Baosheng Science & Technology Innovation Co.,Ltd, Baiyin Non-ferrous Changtong Wire & Cable Co.,Ltd and Shanxi Taigang Stainless Steel Co., Ltd. These collaborators have improved their ability of independent innovation during the process of ITER superconducting conductor research and development. By joint efforts, our sample conductors have passed the ITER IO tests on time with good performance. (Zhu Lina Reports)